A reimagined cabover battery electric Semi-truck for short-haul metro-regional applications

SPECIFICATIONS

| WHEELBASE | 186” |

| EXTERIOR WIDTH (EXC. MIRRORS) | 100.3” |

| INTERIOR HEIGHT | 80.6” |

| BUMPER TO BACK OF CAB | 88.6” |

| CAB TO AXLE (CENTER OF TANDEM) | 152.7” |

| REAR AXLE TO END OF FRAME | 58.8” |

| MAX HEIGHT FROM GROUND | 157” |

| GROUND CLEARANCE | 7.8” min |

| CURB-TO-CURB TURNING RADIUS | 24.9’ |

| WALL-TO-WALL TURNING RADIUS | 27.8’ |

| STARTABILIT Y | 16% |

| MAX SPEED | 70 mph |

| RANGE | Up to 330 mi1 |

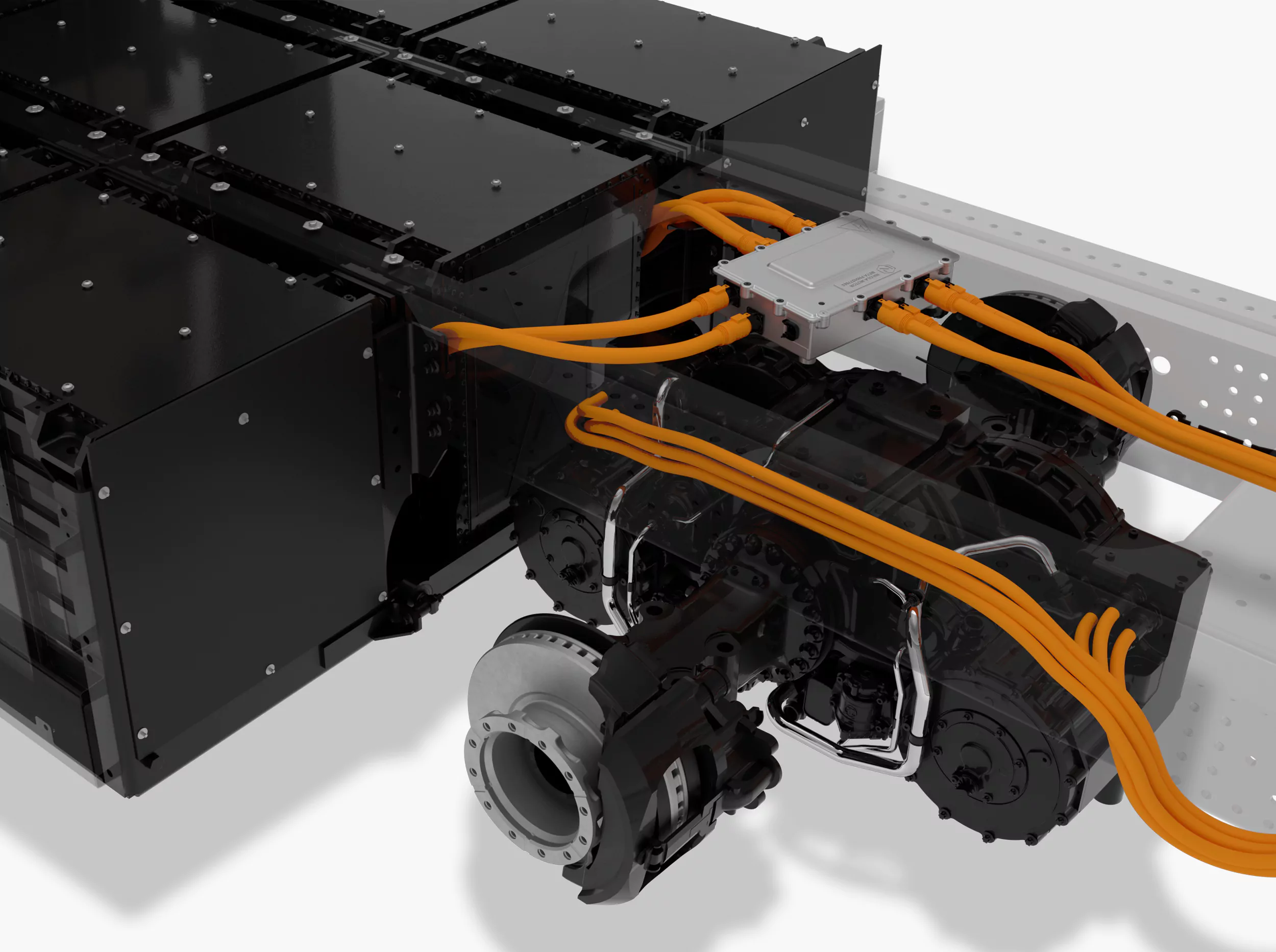

| TOTAL BATTERY CAPACITY (9 PACK) | 738 kWh |

| USABLE BATTERY CAPACITY (9 PACK) | 613 kWh |

| CONTINUOUS POWER | 645 HP / 480 kW |

| INSTANTANEOUS POWER | 1,069 HP / 797 kW |

| CONTINUOUS WHEEL TORQUE | 12,500 FT-LB |

| E-AXLE GEAR RATIO | 21.6 |

| CONNECTOR TYPE | CCS1 |

| CHARGING TIME | 90 minutes2 |

| BATTERIES | (2) 12V 170 Ah Batteries (24V total) |

| DATA LINK CONNECTOR | OBDII Connector |

| POWER SOURCE | 12V DC Receptacle & USB |

| FAN DRIVE | Electric Fans |

| FRAME RAILS | RBM: 1.2M in-lbs, Height: 12”, Thickness: 5/16” |

| TOW HOOK | 1 Front – Passenger side |

| BUMPER | Aerodynamic Body Color Bumper |

| TYPE (STANDARD) | Virtual Slider, Left Side Release |

| TYPE (OPTIONAL) | Sliding 12″ Travel, Left Side Release |

| LOAD MANAGEMENT | Dynamic Weight Adjustment |

| HEIGHT (GROUND TO PIN CENTER) | 47.5” Unladen and Laden Height |

| LOWEST HEIGHT | 46” Manually Lowered |

| FRONT AXLE GAWR | 17,600 lbs. |

| FRONT SUSPENSION TYPE | Taper Leaf Spring |

| FRONT TIRES | 315/80R22.5 |

| REAR DRIVE GAWR | 20,000 lbs. Tandem |

| TAG AXLE GAWR | 20,000 lbs |

| REAR SUSPENSION TYPE | Air Spring, Tandem |

| REAR SUSPENSION CONTROL | Electronic Controlled Air Suspension |

| DIFFERENTIAL LOCK | Pneumatically Operated |

| REAR TIRES | 315/80R22.5 |

1Range estimate was calculated using data obtained from Nikola proving grounds testing, real-world vehicle operation, and computational-based engineering and validation tools. Actual range will vary based on several factors including use case, vehicle characteristics, driver behavior, and environmental conditions. 280% charge at 350kW (available 2025).

A TURNKEY TRANSITION

End-to-end solutions ensure little to no downtime transitioning fleets.

CHARGING

SERVICE + WARRANTY

CONNECTIVITY

FAQs

What do you want to know about going electric?

We currently offer lease and purchase options through our dealer network.

Yes. We have a suite of comprehensive solutions that range from mobile charging to permanent infrastructure, including an operational assessment and energy optimization. We will work with you to provide the best solution.

The Nikola Bev semi-truck is charged through a Non-Proprietary CCS type 1 connector and a charging station.

Yes. Nikola has developed the Mobile Charging Trailer (MCT) for the Tre BEV. This flexible solution can be leveraged as a bridge until a permanent solution can be found, a backup for events when you need to move away from your permanent infrastructure (natural disasters) or when power is not available (blackouts/brownouts

Electric HD vehicles have fewer moving parts and may require less maintenance. This is currently the case in electric passenger cars and busses, so it is plausible that the same will be true with HD trucks. Without an emissions or fuel delivery system, transmission or driveline, the core mx component items have been drastically reduced which should translate to reduced mx.

Our Coolidge, AZ facility will be the primary production facility for the North American Market.

Nikola trucks can be purchased through our authorized dealers in USA & CANADA.

We have partnered with a world class logistics provider to support, supply, and deliver parts efficiently to minimize downtime.

For Nikola vehicles, both are based on an electric drivetrain. The difference is the system responsible for generating the electric energy (batteries for the BEV; hydrogen fuel cells for the FCEV) that powers the electric drivetrain.

Our truck rides very smoothly with instant power and acceleration. You do not feel the shifting through the gears and it is much quieter than its diesel equivalent. Another difference is regenerative braking which is used both to slow the vehicle down and generate energy that goes back to the battery to assist with range.

Every modern battery system experiences some degree of degradation over its life cycle which can impact the range of an associated vehicle. We strive to limit the impact of battery degradation on vehicle range through the engineering of our vehicle systems and note that proper vehicle operation and maintenance are key to maximizing battery system life and vehicle range.